Swiss Turning In China – Swiss Machining Parts OEM Service

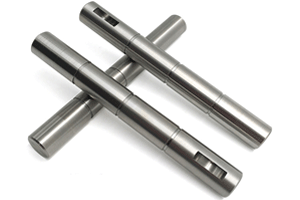

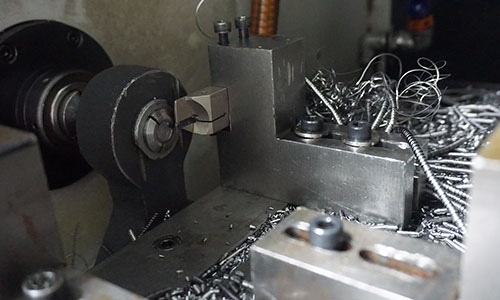

The processes employed to machine our jack screws are CNC Swiss turning, CNC milling, cold heading and CAM Swiss automatic lathing.

PTJ Hardware currently serves a diverse range of markets that include Aerospace, Electronics, Medical equipment, musical instruments, hydraulic and pneumatic valve components, and test specimens and instrumentation.

Our continuing commitment to quality, delivery reliability, innovation and ingenuity has won the respect and appreciation of hundreds of our customers. We invite you to contact our engineers and let them help with your current manufacturing needs.

For over 15 years PTJ Swiss machining company has been crafting precision-machined parts for global companies, becoming an integral part of the supply chain of many industry-leading manufacturers.

Our employees have a real passion for manufacturing, for getting down to the nitty-gritty of making complex machined parts that are Intended to perform critical functions in our customer’s products.

We see ourselves more as partners with our customers, trying to find new ways to make their parts perform better, last longer and cost less. By doing this we help our customers win a greater market share which, in turn, results in more business for all of us!

Swiss Turning Parts And Case Studies

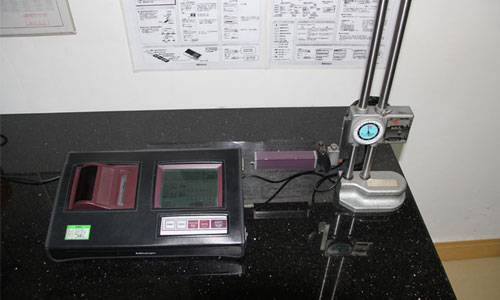

At PTJ, we utilize both conventional screw machines as well as state-of-art multi-axis CNC turning equipment so that we can guarantee our customers that they are getting the best part for their money, made using the most efficient process.

We can machine virtually all metals and plastics in sizes ranging from .0625″ up to 3 ½” in diameter. We can efficiently process low volume orders using generic tooling on CNC lathes or we can tool your job to run on custom-designed machinery that is among the fastest in the world!

When a part cannot be completed in one operation on our machines, our high speed vertical machining centers and CNC chuckers can finish your part with only a minimum of additional set up time needed.