An Young Impeller CNC Machining Shop

In the south of China’s Guangdong Province, Dongguan City has been dubbed “China’s No. 1 Manufacturing County” thanks to the rapid development of the private economy and a strong manufacturing base. Be-Cu is one of the young local manufacturing companies focusing on impeller machining, but they have successfully entered the complex five-axis milling field and occupied an important position in it. How did they succeed? What challenges have you encountered along the way? In this issue, with these questions, let us walk into Be-Cu and uncover the mystery of the processing experts behind him.

Be-Cu, which is currently flourishing in the field of impeller processing, quickly locked its target on the popular “auto impeller” processing after entering “five-axis processing” by a coincidence. Facts have proved that their choice is extremely valuable. . “Automotive superchargers are a popular industry in recent years, which provides us with an opportunity to enter this processing field.” said Xu Jie, manager of Be-Cu Precision Processing. He was tinkering with a few multi-blade milling cutters to profile the blades of the impeller before opening up with us.

According to Manager Xu, the early turbochargers were relatively simple in structure and did not require high precision of the impeller, so they were mainly manufactured by casting.

With the continuous change and strictness of traditional internal combustion engine power and emission standards, the demand for turbochargers has increased rapidly, and at the same time, the speed range and air flow of the engine have also undergone great changes. For example, the impeller of a modern turbocharger has 12 to 30 blades, arranged in radial curves, and the blades are mainly complex three-dimensional curved surfaces, and the wall thickness is usually less than 0.5mm.

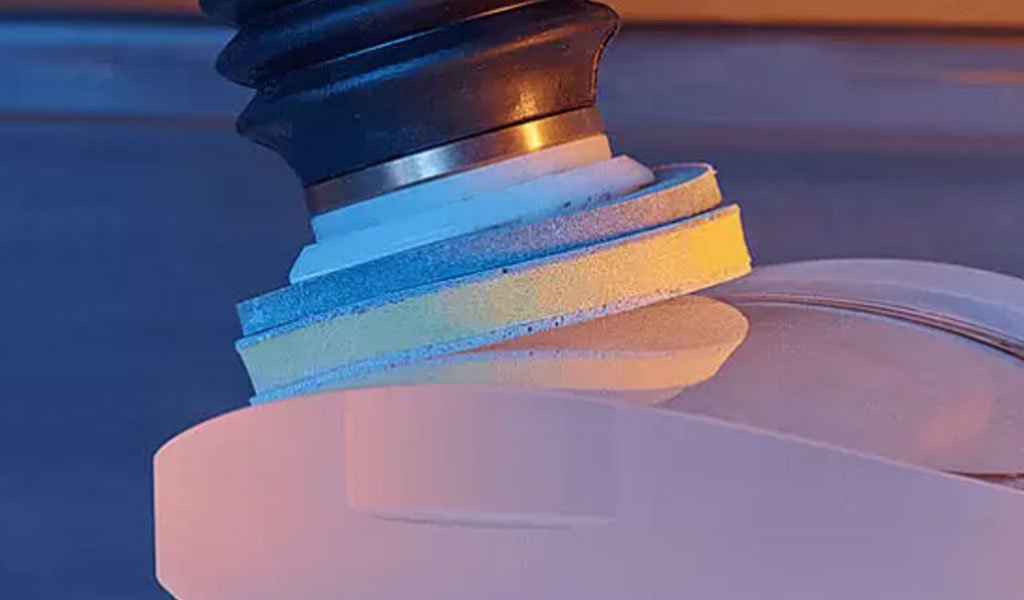

On the other hand, in the processing of turbocharger impellers with complex shapes, most of them also put forward many requirements such as surface finish. These all bring new challenges to the machining of impellers in the field of automobile manufacturing. “Only with the help of a five-axis machining center can we ensure that the tool moves smoothly on the curved surface without missing every point. Makino’s machine tools perform very well as a professional five-axis machining center,” he said.

Unlock the new skills of impeller processing Makino God assists

Manager Xu still remembers the scene when he first started impeller processing, “At first, we didn’t know much about processing equipment and five-axis processing, so we chose a general-purpose processing machine tool from Germany. At that time, we processed various Type impellers, including turbo impellers for automobile superchargers, ship superchargers, generator set superchargers, etc., and compressor impellers, etc. After constant exploration and market wait and see, we finally set our goal on automobile supercharger on the turbocharger.” However, Manager Xu and his processing team soon encountered a bottleneck, “When the original general-purpose processing machine tool encountered the small impeller in the automobile supercharger, the disadvantages of high cost and unsatisfactory efficiency began to emerge. .The value for money is very low, ‘not worth it’.”

Now, in Be-Cu’s processing workshop, the cylindrical aluminum bar is sawed off as needed, and then turned to a rough outline, and then transferred to the next five-axis machining center for blade milling, and finally the Holes, contour lines, etc. are turned to complete finishing forming. To put it simply, from blanking, pre-turning, five-axis forming, to the final finishing – a delicate impeller is born. Benefiting from the significant improvement in the efficiency of five-axis machining, the total machining time of a single part is only about ten minutes, which is much improved than before.

The heroes behind the five-axis milling are naturally the small horizontal machining center N2 of Makino Machine Tool and the high-performance vertical machining center L2. “When we started looking for an economical machining solution for the small impeller of the automobile turbocharger, the compact appearance and mature processing application of the Makino N2 machining center attracted us deeply. There are indications that N2 will open the milling of the small impeller of the automobile for us. new horizons”.

It is understood that for machine tools, the most difficult thing when machining impellers is the matching of programming and 5 axis cnc machining service. The Makino N2 machining center machine tool is equipped with a mature FANUC numerical control system (FANUC), which has excellent high-speed dynamic performance and stability, and is easy to operate. In addition, it has an agile feed shaft, a high-feed drive shaft, and a high-torque, high-rigidity electric spindle that can complete rough machining to finish machining at one time, greatly improving machining efficiency and reducing tool costs.

After N2, Be-Cu purchased Makino’s L2 machining center in order to consolidate and expand its strength in batch processing of automotive turbocharger impellers. It is also Be-Cu’s trust and close cooperation that unlocked new skills in impeller processing for Makino’s star product L2. According to Manager Xu, this L2 machining center, which is known as “reducing the cost of small parts processing production lines”, can realize semi-automatic impeller milling thanks to the advantages of tooling and fixture settings, which significantly reduces the company’s cost in automotive impeller processing. aspect of the overall processing time. As a high-performance machining center, L2 has the characteristics of compactness, high rigidity, high speed, and high efficiency, which is the gospel of small parts processing. Although it has only been launched for a few years, nearly 600 units have been sold worldwide, which shows the response from users.

“Even for processing that requires a contour accuracy of 0.05-0.1mm and no flaws in the appearance, the performance of L2 is reassuring.” At present, the annual production capacity of Be-Cu in automotive impellers is about 80,000 pieces, with annual sales About 10 million yuan. Among them, Makino Machine Tool undertakes 30%-40% of the processing volume. Different from other machine tools, Makino machine tools are mainly aimed at some orders for large-volume and continuous processing.

Based on the overall improvement of the future market trend and the current production capacity, Be-Cu has added two L2 machining centers. “In the future, we will also lock in the direction of automotive supercharger impeller processing, and plan to increase cooperation with supercharger OEMs.” According to Manager Xu, “Currently, Be-Cu has cooperated with several major domestic supercharger OEMs. Therefore, the demand for advanced processing technology will continue to rise in the future, and we look forward to continuing to cooperate more closely with Makino.”

According to an authoritative report, the allocation rate of turbochargers for automobiles in china has increased from 23% in 2014 to 32% in 2016. Judging from the situation so far in 2017, major car companies continue to increase their efforts to launch turbocharged models, and the growth trend remains unabated. As the demand for energy saving and emission reduction of automobiles intensifies, it can be seen that the demand for aerospace cnc machining or automobile turbochargers will continue to grow in the future, which brings new opportunities for the processing of supporting impellers.