The value and significance of the division of production and processing stages in hardware processing

Although hardware processing is the processing of small parts and accessories, production management and on-site management must refer to scientific management systems, standards and methods for various production elements on the production site, including people (workers and managers), machines (equipment, equipment, etc.). Tools, station equipment, fixtures), materials (raw materials, accessories), methods (processing, testing methods), rings (environment), letters (information), etc., carry out reasonable and effective planning, organization, coordination, control and testing, so that It is in a good state of combination to achieve the purpose of high-quality, high-efficiency, low-consumption, balanced, safe, and civilized production.

Therefore, we are doing hardware processing and will divide the production and processing stages of hardware processing, which are mainly divided into the following stages

Ensure the processing quality of hardware accessories

During rough machining of hardware parts, the cut metal layer is thicker, the cutting force and tightening force are large, and the cutting temperature is also high, which will cause large deformation. According to the machining stage, the machining error caused by rough machining can be corrected by semi-finishing and finishing, so as to ensure the machining quality of the parts.

It is convenient to find the defects of the processing blanks of hardware accessories in time

Various defects of the blank (such as pores, sand inclusion and insufficient allowance of castings) are found after rough machining, which is convenient for timely repair or scrapping, so as to avoid unnecessary waste caused by continued processing.

It is convenient to arrange the heat treatment process

After rough machining, stress relief heat treatment is generally arranged to eliminate internal stress. Before finishing, final heat treatment such as quenching is arranged. Distortion caused by heat treatment can be eliminated by finishing.

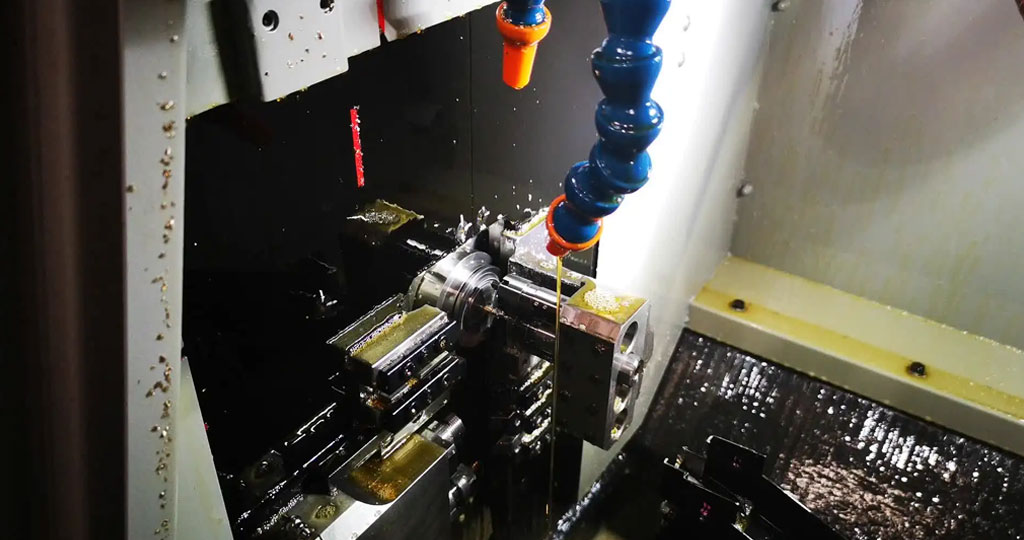

Reasonable use of hardware accessories processing equipment

The rough machining allowance is large, the cutting amount is large, and the machine tool with high power, good rigidity, high efficiency and low precision can be used. The finishing cutting force is small, the damage to the machine tool is small, and the high-precision machine tool is used. In this way, the respective characteristics of the equipment are brought into play, which can not only improve productivity, but also prolong the use of precision equipment.